Photo 1: Wall Decor Evolution

Photo 1: Wall Decor Evolution

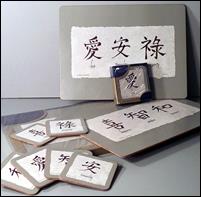

The center 14x14" open edition collaged character for "Spring" from Wild Apple Graphics originally printed in 1998 has been licensed as a resin plaque (L), ceramic tile (framed top), and 3-D metal sculpture (R).

Shop any discount store (Marshall's, TJMaxx...); decorator chain (Linens 'n Things, Bed Bath & Beyond...); or department store (Kohl's, JC Penney's, Macy's...) and you'll find a vast selection of open edition images that have been transformed into plaqued, canvas wrapped, and three dimensional metal images. Framed art is not the only option these days. Framing turned into resin wall plaques, which have given way to metal versions of the same, as well as tiles (photo 1). But it all began with open editions for framed art and their variation on a theme called plaques.

Photo 1: Wall Decor Evolution

Photo 1: Wall Decor Evolution

The center 14x14" open edition collaged character for "Spring" from Wild Apple Graphics originally printed in 1998 has been licensed as a resin plaque (L), ceramic tile (framed top), and 3-D metal sculpture (R).

Plaquing Yesterday and Today

The practice of plaquing as we know it in the framing industry has been around since the early 70s having been introduced into the United States from Canada by Drytac Corporation. Richard Kelley relocated from England to Canada in 1963 and started up the dry mounting manufacturing company Drytac Corporation, set on meeting the creative needs of the mounting and laminating customer.

In 1971 he began importing and distributing giftware from the UK which included mounted/laminated placements backed with cork. This was a new product to Canada and soon became a huge success. When he decided to manufacture them himself with a machine he had found in England, it became an immediate success when he received an order for 24,000 coasters. Soon after he began to promote the idea of laminated pictures and photographs to framers and photographers...and plaquing was born.

Plaquing is the process of mounting a print with a permanent tissue adhesive to a decorative, routed, painted board of pine, masonite or MDF, which is then surface laminated with a protective vinyl heat set sheet rather than with traditional frame and glass (diagram 1). Though a huge industry in Canada and Europe ever since its introduction, plaquing never really took off in the US. In September 2000, HUNT Corporation (now Elmer's Bienfang) began demonstrating plaquing using their tissues and laminates during the Atlanta framing show. Though it is commercially done with hydraulic heat presses in Canada, this technique has always been possible in manual mounting presses here in the States, but never embraced until the new millennium.

Plain, Flat, Flush and Float Mounting

Plain mounts (aka flat mounts) are the most basic forms of plaque print presentation. When a print or photograph is premounted with a permanent adhesive, trimmed to smaller size than the substrate, tacked and mounted to the center of a backing board of masonite, MDF, foam or mount board it is called a plain mount. Photographs are commonly plain mounted onto display boards as 11"x14" photos onto a 16"x20". Borders are generally 2-3" around and though this is not the preferred method for glazing and framing, it is frequently used for photo storage.

When a mounted image extends clear to the edge of the substrate and is not matted it is known as flush mounting and doesn't apply to plaquing because of the visible colored edges of the board. A flush mount print/board unit may be bevel, reverse bevel, or square cut at the exact photo edge to create increased dimension (diagram 2). If mounting photos for storage, flush mounting would defeat the purpose of protecting photo edges from damage by trimming the board to the image edge, allowing it vulnerable to dents and bending.

Basic plaquing is the practice of mounting and laminating an image to a painted decorative edged board (photo 2). When the plaque is then backed to a ⅜", ¾" or 1" solid wood piece it is a box mount; when it has only side pieces applied to the plaque it becomes a hollow box; and when the plaque appears to be suspended over a smaller wood frame or is backed then mounted to another piece of wood it is a float mount (diagram 3). The basic plaque, box and hollow box all have the structure and appearance of a solid unit with the image mounted to its surface. The process of mounting a smaller box to the back of a plaque, or a plaque with a spacer to the surface of a box is often referred to as float mounting because the plaque appears floated off the wall.

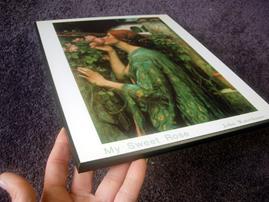

Photo 2: The Basic Plaque

Photo 2: The Basic Plaque

The open edition image, My Sweet Rose, was mounted and laminated with a satin matte vinyl to a piece of 9x12" MDF with its routed edges painted black to contrast against the white paper edges of the art.

Materials and Process

Rigid board surfaces most often selected for this technique include ⅛" Tempered Masonite®; ½", ¾", or 1" pine boards; ⅜" to 1" MDF (Medium Density Fiberboard); and sanded plywood. When producing your own in-house plaque, any surface vinyl laminate finish or texture of: gloss, satin matte, matte, linen, canvas, or heavy canvas may be used. Bevel edges may be either painted or stained with plaque appearances being varied with assorted routed edge profiles. Acrylic paints and stains make good sealers, dry quickly and clean up with water.

Plaquing is simply a matter of mounting and laminating the image. Premount a sheet of permanent tissue adhesive to the back of the print in a F 200 degree press. Cool and trim away excess adhesive to the exact desired size of the face of the prepared plaque. Tack the image in place, cover with a sheet of vinyl heat-set laminate also trimmed to exact dimensions and align over the print. Cover with overlay sponge, place in a release paper envelope and into a pre-heated press of manufacturers' temperature specifications for the selected laminate for enough time to thoroughly mount the vinyl film (diagram 4).

In-house or Commercial

The process of plaquing has assorted names depending on the company promoting the concept. Drytac calls it plaquing; Bienfang calls it plaque art, The Print Mount Company calls it Plak Art; and I have seen it advertised commercially in art stores and trophy shops as Plaque Lamination. Whether known as plaquing, plaque art, Plak Art, or plaque lamination; the concept, process, technique, and equipment remain basically the same, as is the end product. The biggest decision is whether to offer it as an in-house service, get into mass production, or send it out to a commercial company as orders come in. Commercial companies who offer plaquing include: Print Mount Plak Art; Unique Mounting Services; Off the Wall Lamination; ColorPak; Plastiplak; or MES Lamination.

The Drytac Corporation sells a high tech wood edger for plaquing called the DES-1, which is designed for large scale production. It routes, finishes, and applies the color to the edges of plaques in preparation for surface mounting and lamination. It is capable of bonding high temperature foils between 300°F-365°F for the ultimate in decorative application. It also boasts a continuous feed conveyor to move the plaque from the shaping station to the cleaning station.

Artist and Publisher Copyright

As an artist for Wild Apple Licensing I have had mounted and laminated placemats and coasters sold of my Asian calligraphy and art since 1999 (photo 3). Any time an open edition image or photo is transformed from its original form to that of another by an outside company there are copyright issues. Framers must always consider the copyright issue when creating a new item such as a canvas transfer or plaque from published open edition images when the initial intent of the art is to be placed in a frame.

Photo 3: Plaqued Placemats

Photo 3: Plaqued Placemats

These are sets of mounted and laminated placemats and coasters as licensed art by Wild Apple Licensing to Pimpernel. They are open edition images mounted to thin boards then backed with a layer of cork for insulation and protection for furniture and glass top tables.

When images are purchased with the intent to vary their form and be sold commercially, regardless of laminated placemat to key chain, all must be contracted for and approved of by the artist and their licensing company. Royalties will need to be paid. When an image is mounted and laminated onto a placemat or turned into a serving tray, without the artist's permission there is an infringement of artist copyright, which is illegal.

The same is true with canvas transferring or plaquing. If an open edition image is to be plaque mounted as a service for a customer is it generally a legal practice, but images slated for production with the sole intention of marketing them as a new form of wall decor requires permission and/or a licensing contract to alter the art.

The artist and publisher have the right to decide if they wish their printed art placed on a painted wood plaque, box, placemat, coaster or tray. As an artist I have been called numerous times by my publisher to obtain permission to place my small Asian images on ceramics, canvas or wood as transfers or plaques, but always as a licensed product offering royalties. Framer be sensitive to the alteration of artworks and consider what you are doing to the intended original.

Where does Plaquing Fit In?

The technique of plaquing has been in our industry for nearly half a century. It is currently thriving in home decor markets, particularly the OEM (original equipment manufacturer) market that supply art to furniture and discount stores. As professional custom picture framers the idea is to glaze and place beautiful mouldings around gorgeous multiple mats for fine art presentations, not really mounting and laminating to a piece of wood.

Although we may ask the question of the validity of this technique in custom framing, we also realize as we venture into the gift market of ceramics, textiles and perhaps jewelry that there is much more to a gallery and custom frame operation than merely picture framing. The real question here might be if offering plaquing as an option to framing will bring in additional revenue by targeting a currently untapped market, or will it water down the desire for wider mats, fillets, and glazing on images for home decor.

Any framer who dry mounts should also be offering plaquing as a contemporary, durable alternative to glazing. Since it is nonbreakable, warp, humidity, and moisture resistant plaquing is the perfect alternative to traditional framing for bathrooms, kitchens and kids rooms.

END

Copyright © 2006 Chris A Paschke

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com