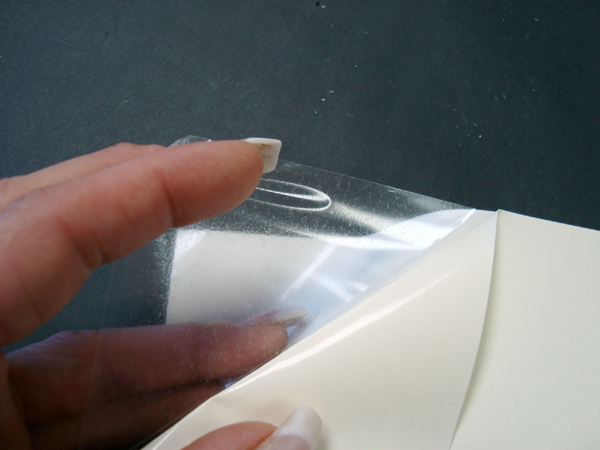

Photo 1

Photo 1

Sold in flat sheets, PerfectMount film has two liners and the film has an inner carrier that prevents breakage or air bubbles, but disallows it to self-shape as with PMA and 870 pure films.

Pressure-sensitive products have been a mounting staple in frame shops for decades. these adhesives are available from numerous manufacturers and have been successfully used for open edition prints, reproductions and photographs because of ease of use, health safety, economy and more recently heat sensitive art.

In "The Permanence and Care of Color Photographs", Henry Wilhelm, 1993, the 3M Company stated: "3M tapes and adhesives form a physical bond to surfaces that are not soluble in water. They can be loosened with solvents or reversed with heat but...are not without risk of damage to the artwork...we know most of our adhesive products have an indefinite age...we do not have a test that will predict how a product will hold up after 50 or 100 years...these products are designed for general purpose use in bonding on items of limited value...". The current ISO 18902:2007, section 4.5 Adhesives states: "pressure-sensitive adhesives have poor stability characteristics and should be avoided. Always research any self-adhesive board products for its individual specifications and be aware of claims and limitations when choosing any product. All this said, sometimes a pressure-sensitive is the only logical choice for mounting. Such is the well known case surrounding digitals.

Types and Tack

A pressure-sensitive adhesive (PSA or P-S) is a permanently tacky thermoplastic substance that bonds to an untreated surface at room temperature, with only the application of slight pressure. By definition P-S adhesives differ from every other category of adhesive. They may have slightly lower bond longevity than heat-set adhesives, but because of their permanent tack, they are always ready to bond to almost any surface with only thumb pressure. They are dry, synthetic adhesives that are clean, easy to use, odorless and require no heat or solvents. They are available as both films to be applied to any substrate of choice or with the PSA already applied to a selected substrate, often called self-adhesive (SA) boards.

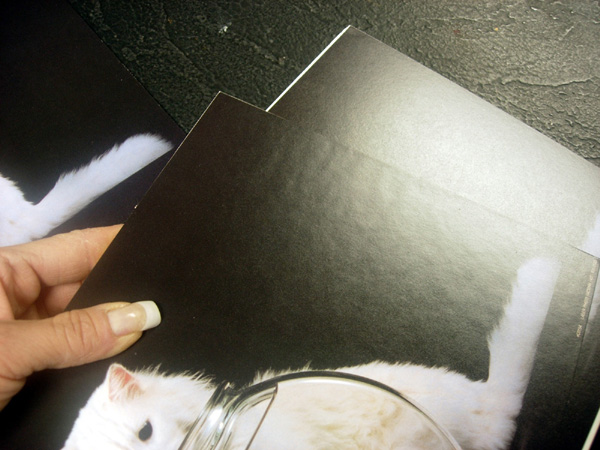

Photo 1

Photo 1

Sold in flat sheets, PerfectMount film has two liners and the film has an inner carrier that prevents breakage or air bubbles, but disallows it to self-shape as with PMA and 870 pure films.

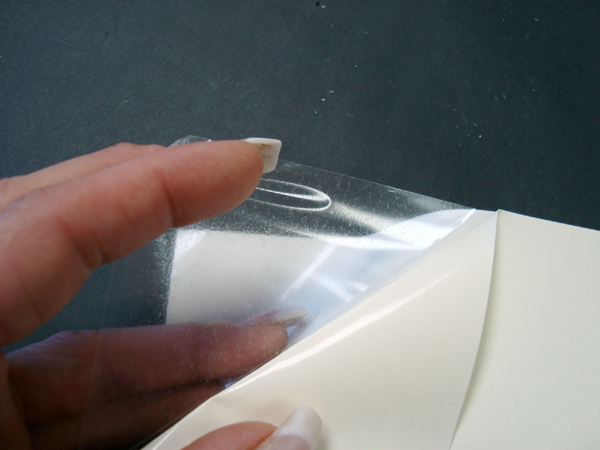

Photo 2

Photo 2

This pure film low tack adhesive is like a wide sheet of ATG tape that breaks and rolls up between your fingers when lifted from the liner. Check for holes and breaks in the film before final application, as these can allow for bubbles later.

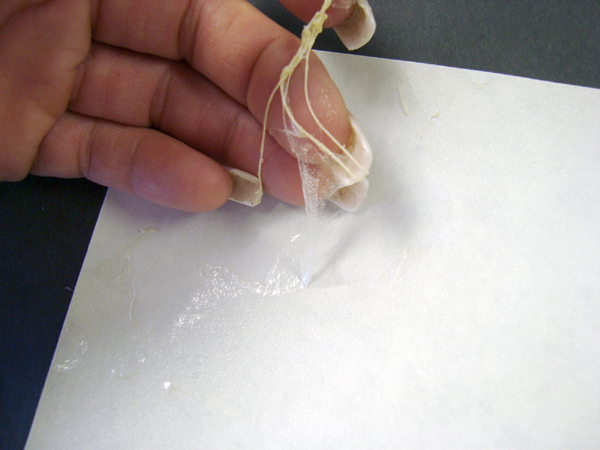

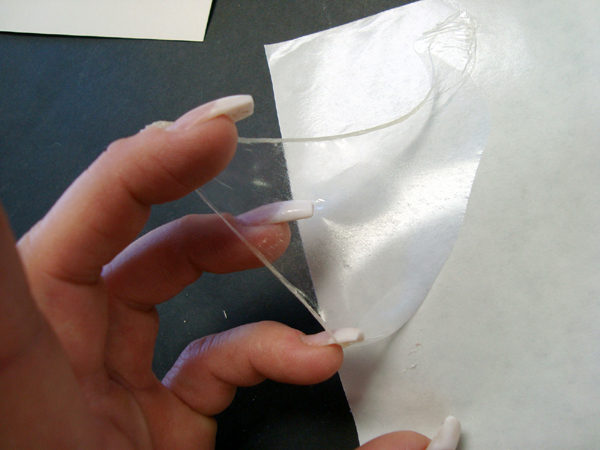

Films come with single or double release liners depending on whether they have a carrier sheet with adhesive on either side or if it is pure adhesive. Crescent PerfectMount Film is a P-S adhesive applied to either side of a thin polyester carrier which is only available as a flat sheet with release liners both sides (photo 1). 3M Positionable Mounting Adhesive - or PMA - (photo 2) and the Neschen products come rolled on a single liner even though Gudy 870 is pure film (photo 3) and 831 has a thin paper carrier. Self-adhesive paper boards and foam center boards have only one side coated with PSA covered by a liner. Boards are available as ⅛" and 3/16" foam, X (medium), XX (heavy), and ⅛" (extra heavy) weights. Foam comes ⅛" and 3/16" (photo 4).

Photo 3

Photo 3

A pure film high tack adhesive this sheet lifts from the liner while better maintaining its shape. This film will manually apply to a board or back of the art with little chance of air bubbles.

Photo 4

Photo 4

(L-R bottom) Elmer's Permanent SA Foam, Crescent PerfectMount SA Foam, Bainbridge Adhesive Foam, Alcan SA Foam-LT, Gilman Insite Reveal HT, Drytac P-S Foam. (Top) Crescent PerfectMount SA Board, Bainbridge SAX, Savage FilmTax Hvy Wt, Drytac P-S Black Polystyrene, and Drytac P-S Black Gatorfoam. Tested boards not shown: Hartman HarTac, and Savage Prestax ProCore.

High tack (HT) PSA is aggressive and most difficult to hand apply since it is not repositionable and is often recommended for use with roller machines. They immediately grab to a smooth nonporous item, like a photo or clay coated foam board, and may not be repositioned. Medium and low tack PSA are the one most frequently used in picture framing. They may be somewhat repositionable during mounting with porous papers, but even repositionable self-adhesive boards will grab more aggressively to a smooth or coated material. Low tack (LT) is not well suited to the longevity of framing demands, and is least favorable on self-adhesive boards for display art.

When an image is manually applied with a hand rub to a P-S board it may only activate 25% of the adhesive capability. In order for the adhesive to have a higher percentage of activation it needs to be burnished down after application or run through high pressure rollers. Even placing in a vacuum frame is not as good as burnishing. The higher the adhesive tack, the more aggressive the initial bond and the possible longevity of that mount. But be careful of arm pressure as it is easy to dent some foam boards during application (photo 5).

Photo 5

Photo 5

Too much manual pressure with a brayer or squeegee can indent a foam center board as above. A dry mount press uses only 2-4 psi while arm strength is much higher.

Strength and Permanence

Bond strength - or tear strength - is a better phrase than permanence when referring to adhesives because of the subjectivity of what might be meant by permanent. In the case of a PSA, permanent means impossible to remove without destruction of the substrate or mounting, such as with a mailing label. A removable PSA may be removed without harming the substrate in any way or leaving adhesive residue, like a post-it-note. The act of permanently bonding any art to a backing is never a preservation method. And regardless of how stable and inert any adhesive may be, it is the adhesive absorption into the art is what makes a mounting method non-reversible and non-preservation.

Historically, coated papers are the most difficult to adhere (RC photographs) because of their lack of absorption and a require softer more aggressive PSA for immediate bond strength, making a high tack board the best choice. Film PSAs are best for use with porous paper. 3M PMA and Neschen Gudy 870 and 831 all show tear strength for paper, but only 831 aggressively held photos right away.

Application technique and use temperature also effect bond permanence. A permanent high tack pressure-sensitive applied at room temperature may fail at freezing temperatures if placed outside, or in an excessively humid bathroom. High moisture content (humidity) also makes pressure-sensitive adhesion difficult, as moisture is a physical barrier to adhesion and long term bonding. Coldness to the touch is often an indicator of moisture content in boards. Dry storage is imperative to both prevent unwanted warpage and to insure maximum PSA bond strength. Just as removable pressure-sensitives may not always remove, permanent pressure-sensitives may not always be permanent. Never select a pressure-sensitive product prior to knowing the exhibition or end display conditions.

June Testing 2006

In June 2006 I completed a test study to compare various PSA products commercially available in the framing and photo industries. Films included 3M PMA, Crescent PerfectMount Film, and both Neschen Gudy 870 and 831. Paper board and foam board products were from Alcan, Bainbridge, Crescent, Drytac, Elmer's, Gilman, Hartman and Savage. Board thicknesses ranged X, XX and heavy weight while foam boards were limited to 3/16". Boards were compared for degree of tack, orange peel, denting, shear and tear strength plus being put through additional tests to check humidity, heat and cold tolerances.

Boards were precut into 8x10 sample sizes and tested by manual application using brayers to mount porous paper (photo 6), RC photograph, polyester encapsulation, light fabric, digital canvas, and raw canvas. All test materials were applied using identical methods of folding back the top edge of the liner; aligning art; pressing against exposed adhesive; and pulling liner from beneath. The removed liner was then used to cover the art and burnish it in place with a 4" wide soft rubber roller, followed by a hard rubber brayer (photo 7). A squeegee was used at times to insure air removal and adhesive activation, particularly with nonporous items.

Photo 6

Photo 6

All mounted kitten posters were laid out for testing after sitting under a weight for 12 hours. Notice the dents and T-peeled corner in lower right corner sample.

Photo 7

Photo 7

Like the kittens, all photo samples were laid out for examination after the 12-hr weighting period. Note the Speedball hard rubber roller black wheel) and soft rubber brayer above the photos. Photos courtesy of Bienfang/Elmer's Products.

Mounted art was checked for immediate grab, 15 second bond, 15 minute bond, then placed under an even weight for 12 hours to cure for final T-peel test. All films were first applied to precut Artcare Archival Foamboard 3/16" and AlphaMount Artcare 8743 to first create the self-adhesive board and foam, then the art was applied in the same manner above and placed under a weight for 12 hours.

All mounted samples were then subjected to a series of extremes in an attempt to simulate real life indoor-outdoor situations. Samples were shot with direct steam for 15 seconds from a hand steamer to simulate moist heat from a bathroom shower, then immediately checked for bond and thermoplastic reaction. They were wrapped in airtight plastic and frozen for 12 hours to represent a Minnesota garage in winter, then checked for T-peel, weakness or bubbles. Dry heat was applied in a F200 oven for 1 hour to test for slower, dry heat reactions as in the car trunk during Arizona summer. Since some of the adhesives are thermoplastic the bonds were weakened with heating, but generally all held as expected when cooled. The thermoplastic adhesive requires immediate separation when removed from the oven for the bond to release, but no visible bubbles occurred. A thermoplastic cooled without pressure will never have maximum bond and bubbles are likely.

Test Observations

Though an assortment of materials were tested, only the porous poster and RC photo are reported in this column, see spread sheet for additional info. All boards, regardless of low or high tack, bonded well to the porous kitten poster, which was expected. The real surprise was Elmer's Permanent Self-Adhesive Foam Board held up through all the tests including the bond for digital and raw canvases, only rivaled by the Drytac line of P-S Pre-Coated Mount Board products. Almost all samples met T-peel tear strength for paper and porous materials, though some took 12 hours under weight to bond. Elmer's, Drytac Gator and polystyrene all had very aggressive immediate grab.

Photo 8

Photo 8

Contrary to popular belief even paper can show the ripples of orange peel on a lumpy substrate. Lower kitten shows a typical surface texture on a this PerfectMount Board XX while the PerfectMount Foam sample beneath it is smooth.

Photo 9

Photo 9

Orange peel showed up routinely on the paper board substrates Bainbridge SAX (top L), Savage Prestax ProCore (top R) though both held very aggressively. The Alcan SA Fome-Cor LT showed air bubbles even after the 12 hours (bottom).

Orange peel showed up with paper on Bainbridge SAX and SAXX, PerfectMount XX, Drytac Foam, Gilman HT Foam and Savage FilmTax (photo 8). PerfectMount Foam, Alcan Fome-Cor, and Drytac foam dented with the hand pressure from the brayer. The RC photo showed varying degrees of orange peel on all the X, XX, and heavy weight paper boards, as well as the Alcan Fome-Cor LT (photo 9). All the HT products exhibited 15 second grab while the LT products of Bainbridge SA Foam, Elmer's Quick Stick LT, Alcan Fome-Cor, and all PerfectMount boards required 12 hours to reach basic cure.

Final Review

A total of 23 different films and boards were tested and results prove there are variations between products, thus no one PSA works for everything. Elmer's Quick Stick HT, Drytac Gatorfoam and Stikiboard were the only ones that lightly held fabrics and canvas, paper boards have orange peel, and some clay coated boards have a tough time bonding photos with tear strength even after 12 hours. Then there's Savage NuCor and Prestax ProCore which held lightweight fabrics but would not bond raw or digital canvases (spread sheet*). Interesting results.

END

Copyright © 2008 Chris A Paschke

For more articles on mounting basics look under the mounting section in Articles by Subject.

Additional information on all types of mounting is found in:

The Mounting and Laminating Handbook, Second Edition, 2002,

The Mounting And Laminating Handbook, Third Edition, 2008 and

Creative Mounting, Wrapping, And Laminating, 2000 will teach you everything you need to know about getting the most from your dry mount equipment and materials as an innovative frame designer.

All books are available from Designs Ink Publishing through this website.

Chris A Paschke, CPF GCF

Designs Ink

Designs Ink Publishing

785 Tucker Road, Suite G-183

Tehachapi, CA 93561

P 661-821-2188

chris@designsinkart.com